FOOD CUTTING PRODUCTS

ARE IN OUR DNA

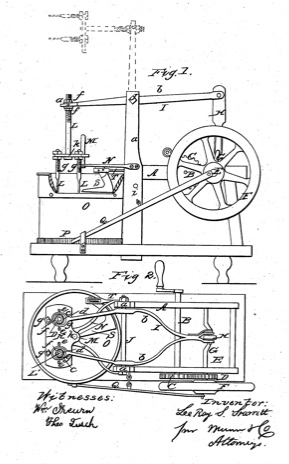

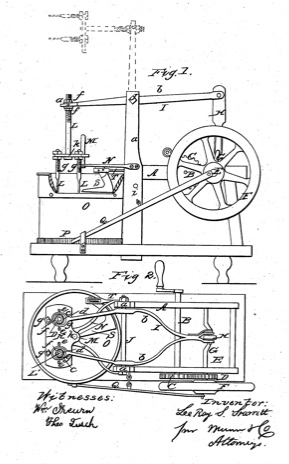

Laroy Starrett’s first invention

was a meat chopping machine (pictured right)

The machine was patented on May

23rd, 1865 – 15 years before Starrett

was founded

FOOD CUTTING PRODUCTS ARE IN OUR DNA

Laroy Starrett’s first invention was a meat chopping machine (pictured below)

The machine was patented on May 23rd, 1865 – 15 years before Starrett was founded

Laroy Starrett – His invention of a meat chopping machine in 1865 marked the birth of the Food Division’s DNA

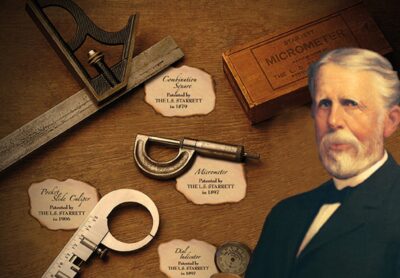

Laroy Starrett is a name that is synonymous with precision tools and measuring instruments. Renowned for his groundbreaking inventions such as the Combination square and micrometers, Starrett has made a significant impact on the world of tools. However, it may come as a surprise to many that his very first product was not related to the field of engineering or manufacturing, but rather, the food industry.

Laroy S. Starrett – The man behind the brand

Born in China, Maine, the USA in 1836 as one of twelve children, Laroy had a typical farm upbringing and had his roots in the soil. Clothed by the wool and flax raised on the farm; one of Laroy’s earliest memories was sitting under the loom and picking up the shuttle which his mother occasionally dropped as she was weaving cloth for their garments.

As he grew older, he joined the men in the fields and at fourteen was trusted to drive the oxen with cartloads of cordwood to Augusta, twelve miles away. It was a 17 hour round trip, often in zero-degree weather. Laroy recalled, “It seems tough to think of it now, but I did not mind it then.”

The Starrett’s being a large family found it a struggle to make ends meet. Laroy’s father had got into debt and the farm would have to be mortgaged as security, hearing this, Laroy at seventeen years old left home and hired himself out. For several years he paid his family his earnings until the mortgage was paid off. Saying that this gave him greater pleasure than putting the money in a bank.

His first job was on a milk farm but by the time he was twenty-six he was able to rent his own 600-acre farm. Never one to follow tradition, his ideas of planting and cultivating often went against all his neighbour’s advice. But they brought him top prices and blue ribbons at the agricultural shows. He bought the first mowing machine in that part of the country and soon paid for it by mowing his neighbour’s hay after his own was in, finally convincing them he knew what he was doing it was expected he would soon have a farm of his own.

His first job was on a milk farm but by the time he was twenty-six he was able to rent his own 600-acre farm. Never one to follow tradition, his ideas of planting and cultivating often went against all his neighbour’s advice. But they brought him top prices and blue ribbons at the agricultural shows. He bought the first mowing machine in that part of the country and soon paid for it by mowing his neighbour’s hay after his own was in, finally convincing them he knew what he was doing it was expected he would soon have a farm of his own.

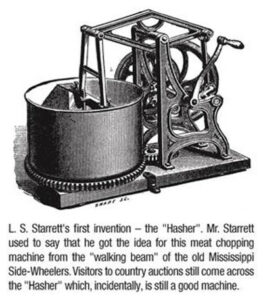

But Laroy had different ideas, he had what he called “invention on the brain” and wasn’t to be sidetracked. In winter and stormy days, he spent his time in a room over the stable which was fitted out as a workshop. Here he developed his first invention, the meat-chopping machine. The ‘Hasher’ he got the idea from the “walking beam” of the old Mississippi Side-Wheelers. Whilst without experience in manufacturing, Laroy had great faith in this chopper and his ability to succeed with it. When the working model was finally perfected, he sold out his farming interests and turned to business. Visitors to country auctions still come across the “Hasher” which, incidentally, is still a good machine.

Getting the ‘Hasher’ on the market was a struggle, everything was new and Laroy had to learn as he went along. Always ready to listen and absorb the knowledge and experience of others, Laroy watched his pattern maker and discovered what was needed to make a good casting. He hired a room, fitted it out, and began turning out his choppers.

By bringing in a silent partner who invested money and by selling sales rights in different countries, Laroy was able to devote more time to manufacturing. The business grew and new premises were needed, a place with more capital and waterpower. He met a businessman from Athol, Massachusetts, who recommended his hometown.

Laroy visited Athol and was impressed by what it had to offer, he quickly moved there and began working with the Athol Machine Company. Soon the meat chopper business was running smoothly, allowing him to turn his inventive genius to other products. Among the patents taken out by Laroy was a line of bench vices and a shoe hook-fastener. This alone was capable of bringing in an independent fortune had he developed it. Instead, regarding it as secondary importance, Laroy sold it for a few hundred dollars, choosing to concentrate his interest in the development of precision tools.

For the next few years, Laroy was working harder than ever and his new products were selling satisfactorily. Nevertheless, as he approached forty he was unable to make a success in a business way that he wanted.

For the next few years, Laroy was working harder than ever and his new products were selling satisfactorily. Nevertheless, as he approached forty he was unable to make a success in a business way that he wanted.

Misfortunes then befell Laroy. His wife died, leaving him with four small children to care for. He lost his hearing. His association with the Athol Machine Company had not been happy and through jealous rivalry, he lost his position. To make matters worse, all the money he had was tied up in stocks, and the Athol Machine Company continued to capitalize on his inventions. Laroy saw no other way but to try to create a business for himself by inventing something useful that people would want.

He had worked at pattern making and used clumsy, fixed-blade try squares. Realising the need for a more handy instrument, he sat at the kitchen table night after night and drew up a design and made patterns of it. His combination square was born and patented in 1879.

Having mastered the art of an exacting steel blade, Laroy turned this knowledge into making steel rules and tapes, turning the phrase ‘if you use tapes with Starrett’s name on them you will make no mistake.’

In 1890, Laroy’s inventive genius turned to the Micrometer, a tool that originated from France, but never satisfied with the slow adjustments of the screw, which required forty revolutions to open or close one inch. Laroy set about devising a micrometer that would be absolutely accurate and capable of being adjusted instantly, stating “It gave me much pleasure to accomplish this to my entire satisfaction.”

In 1895 Laroy patented the divider with trammel.

In 1920, the company added its first gauge, designed to check the curvature in spectacles, to the product line and quickly became the world’s largest innovator and maker of precision calibrators.

Many others have had similar ideas, the difference here was the man. Laroy’s outstanding characteristic was confidence in himself; he was a man who in spite of one setback after another refused to admit defeat. He had the unusual ability, vision, and enterprise, but without his high courage this story of the foundation and growth of “the world’s greatest toolmakers” could never have been written.

Why choose Starrett?

Few companies can boast the trust that Starrett have built over a century working together with customers working in many different industry sectors around the world. You can expect the level of customer service and support that only companies with the history and reliability of Starrett can offer. You buy from Starrett because the quality of every product that we manufacture is assured and certified to be fit for purpose. In sectors like the food industry for example, that is critically important because companies need to comply with very strict health & safety regulations.

What about Starrett’s leadership in South America…

South America is one of the biggest meat producing markets in the world – producing meat of the finest quality. Starrett Brazil is the number producer of food cutting bandsaw blades in South America. To be able to achieve that in such a competitive market, we must supply products of outstanding quality and a 100% reliable service. We marry the technical expertise and quality that we have in Brazil, with our knowledge of the requirements of the UK and European customers. This results in products that offer the perfect balance of quality, performance, and price. We are proud to offer an exciting and expanding product line for the food industry throughout the UK & Europe. Our products offer complete traceability commencing from the initial stage of the manufacturing process ensuring superior quality and safety. All our products are certified to be suitable for food production.

What bandsaw Blades do Starrett offer?

We have developed an extensive range of the most sought-after meat and fish cutting bandsaw blades. Our manufacturing capabilities enable us to maintain control of the quality of our bandsaw blades right from the start of the manufacturing process. We utilise this expertise and our market knowledge to deliver bandsaw blades that optimise performance, increase yield, and minimise waste.

Our range of bandsaw blades included:

- MeatKutter Premium

- MeatKutter Frozen

- CarcassKutter

Similarly, we offer a diverse range of skinner blades that are suitable for most machines in the industry. As manufacturers, we can deliver skinner blades of any length required and ensure the highest quality standards. Our skinner blades are ideal for removing meat membranes, deriding pork, and skinning fish.

What Professional Knives do Starrett offer?

We are excited to offer an exciting assortment of Butcher Knives, designed to cater to Professional Butcher’s and cooking enthusiasts. Our knives are certified by NSF, the internationally recognised organisation that approves products for the food industry. All our knives have a tracking number which guarantees origin identification and traceability and the handles have Sanitized anti-microbial protection to help prevent bacterial growth. Starrett Knives offer the right balance of quality and affordability. Made of high carbon stainless steel, each Starrett knife provides exceptional value for money.

Our range of knives includes:

- Boning Knives

- Steak Knives

- Skinning Knives

- Butcher’s Knives

- Knife Kits for BBQ, Chef’s, and Kitchens

- Sharpening Steels

- Sharpening Stones

Manufacturing and Distribution Worldwide

Starrett has 15 manufacturing and distribution sites worldwide ensuring efficient production, shorter lead times, and reduced shipping costs.

Manufacturing and Distribution Worldwide

Starrett has 15 manufacturing and distribution sites worldwide ensuring efficient production, shorter lead times, and reduced shipping costs.